Understanding the Science Behind Centrifugal Pumps in Modern Engineering

In the realm of modern engineering, centrifugal pumps play a pivotal role in fluid transportation across various industries. These devices, designed to convert rotational kinetic energy into fluid energy, operate under the principle of centrifugal force, making them highly efficient for a range of applications. Understanding the science behind centrifugal pumps is essential for engineers, as their functionality impacts everything from water supply systems to chemical processing and oil extraction. The ability of a centrifugal pump to handle diverse fluids, maintain consistent flow rates, and offer flexibility in design highlights its significance in tackling contemporary engineering challenges.

As we delve into the various types of centrifugal pumps and their applications, we will uncover the intricate mechanics that enable these machines to thrive in a multitude of settings, solidifying their status as a cornerstone of modern engineering practices.

Fundamentals of Centrifugal Pumps: How They Operate in Fluid Mechanics

Centrifugal pumps are critical components in fluid mechanics, relying on the principles of centrifugal force to move fluids. At the core of their operation is a rotating impeller, which converts mechanical energy into kinetic energy. As the impeller spins, it creates a low-pressure area at the center, pulling fluid into the pump. The design of the pump ensures that as the fluid moves from the center towards the outer edge of the impeller, it gains velocity, which is then transformed into pressure energy as it exits through the discharge port.

The mechanics of centrifugal pumps are governed by several key equations and principles, including Bernoulli's equation and the continuity equation. These equations illustrate how energy is conserved throughout the process, balancing kinetic and potential energies as the fluid flows through varying cross-sectional areas. The efficiency of a centrifugal pump depends not only on the design of the impeller but also on factors such as fluid viscosity, temperature, and the operational environment, highlighting the importance of understanding fluid mechanics in optimizing pump performance and ensuring effective fluid transport in various engineering applications.

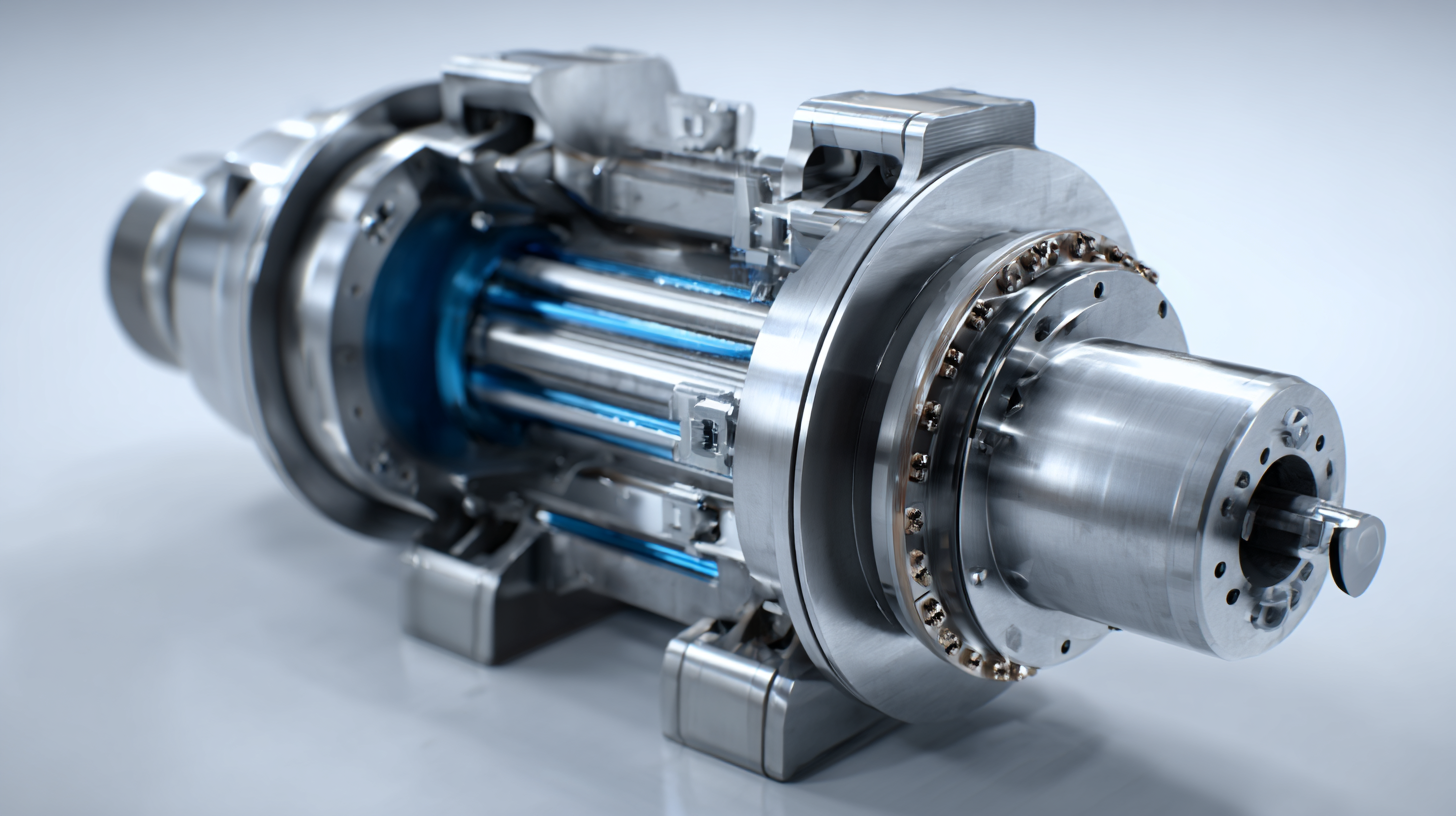

Key Components of Centrifugal Pumps: Anatomy and Functionality Explained

Centrifugal pumps are crucial components in various engineering applications, characterized by their unique anatomy and functionality. At the core of a centrifugal pump lies the impeller, a rotating component designed to increase the kinetic energy of the fluid. As the impeller spins, it draws fluid into the pump through the suction inlet, converting rotational energy into fluid motion. This process is fundamental in applications ranging from water supply systems to industrial processes, with operational efficiencies often exceeding 85%, according to industry reports.

Another essential component is the volute casing, which collects the fluid exiting the impeller and directs it toward the discharge outlet. The design of the volute plays a significant role in managing flow rates and pressure, with the optimal design contributing to a reduction in turbulence and energy loss. Recent advancements have introduced computational fluid dynamics (CFD) simulations to optimize this architecture further, leading to pumps that can handle higher flow rates while consuming less energy. In modern engineering, the performance of these pumps is often quantified using metrics such as the pump affinity laws, aiding engineers in selecting the right pump for specific applications while ensuring maximum efficiency and reliability.

Efficiency Optimization: Balancing Speed and Flow in Modern Designs

In modern engineering, optimizing the efficiency of centrifugal pumps is critical for various industrial applications. Balancing speed and flow is a fundamental aspect that influences the overall performance and energy consumption of these pumps. When designing a centrifugal pump, engineers must consider the specific requirements of the system, including the desired flow rate and the amount of pressure needed. Achieving the optimal speed can drastically improve the pump’s efficiency, enabling it to transport fluids with minimal energy loss.

The interplay between speed and flow in centrifugal pumps is governed by several factors, including impeller design and the characteristics of the fluid being pumped. High-speed operation may increase flow rates, yet it can also lead to cavitation, which damages pump components. Engineers use advanced modeling techniques and simulations to analyze these dynamics and find the right balance. By optimizing the impeller shape and material, and utilizing variable-speed drives, modern centrifugal pumps can achieve remarkable efficiencies while maintaining reliability in demanding environments. This careful calibration ensures that the pumps operate within their best efficiency point (BEP), resulting in reduced operational costs and improved overall system performance.

Understanding the Science Behind Centrifugal Pumps in Modern Engineering - Efficiency Optimization: Balancing Speed and Flow in Modern Designs

| Pump Type | Max Flow Rate (m³/h) | Max Speed (RPM) | Efficiency (%) | Application |

|---|---|---|---|---|

| Single Stage | 100 | 2900 | 70 | Water Supply |

| Multistage | 250 | 3600 | 85 | High Pressure Applications |

| Self-Priming | 80 | 2900 | 75 | Irrigation |

| Submersible | 175 | 3600 | 80 | Wastewater Management |

| Canned Motor | 50 | 3000 | 90 | Chemical Processing |

Applications of Centrifugal Pumps in Various Industries: A Comprehensive Overview

Centrifugal pumps are integral to numerous industrial applications, characterized by their ability to efficiently move fluids through rotating impellers. These pumps are widely used in sectors such as water and wastewater management, oil and gas extraction, chemical processing, and even food and beverage production. The global centrifugal pumps market is forecasted to grow significantly, reaching USD 55.4 billion by 2035, underscoring their essential role in modern engineering.

Tips for selecting the right centrifugal pump involve considering factors like the fluid characteristics, required flow rate, and system head. Proper sizing and material selection are crucial to ensure optimal performance and longevity of the pump. Additionally, regular maintenance and monitoring can greatly enhance the efficiency and reliability of these pumps, preventing costly downtime.

In sectors such as sewage handling, centrifugal pumps excel due to their robust design and ability to handle various types of liquids, including slurries and chemicals. The ongoing growth in the sewage pump market signifies an increasing reliance on these pumps to meet environmental and infrastructure demands effectively.

Applications of Centrifugal Pumps in Various Industries

This bar chart illustrates the number of applications of centrifugal pumps across various industries. The water supply sector has the highest number of applications, followed by oil and gas, chemical processing, food and beverage, and wastewater treatment industries.

Innovations in Centrifugal Pump Technology: Trends Shaping Future Engineering

The centrifugal pump industry is currently witnessing remarkable advancements that are reshaping the landscape of modern engineering. According to a recent report by Global Market Insights, the centrifugal pump market is projected to exceed $40 billion by 2027, driven by increasing demand across sectors such as water and wastewater management, chemical processing, and oil and gas. Innovations in materials and design, such as the integration of composite materials and advanced hydraulics, are enhancing pump efficiency and durability, thereby reducing operational costs and downtime.

Moreover, the rise of smart technology in centrifugal pumps is a game-changer. Many contemporary pumps are now equipped with IoT capabilities, allowing for real-time monitoring and predictive maintenance. A study by Technavio indicates that these smart pumps could lead to energy savings of up to 30%, providing substantial economic benefits to industries that rely heavily on pump systems. As energy efficiency regulations continue to tighten globally, the development of variable speed drives and energy-efficient designs is becoming essential, paving the way for more sustainable engineering practices in the future.

Related Posts

-

The Ultimate Guide to Choosing the Right Centrifugal Pump for Your Needs

-

How to Choose the Right Wastewater Package Plant for Your Needs

-

10 Innovative Methods for Effective Waste Water Removal You Need to Know

-

What is the Role of Waste Water Treatment Plants in Sustainable Water Management?

-

5 Essential Tips for Choosing the Right Screw Pumps for Your Business

-

Revolutionizing Urban Sustainability with Advanced Waste Water Treatment Equipment Solutions