How to Choose the Best Industrial Waste Water Treatment Systems for Your Needs

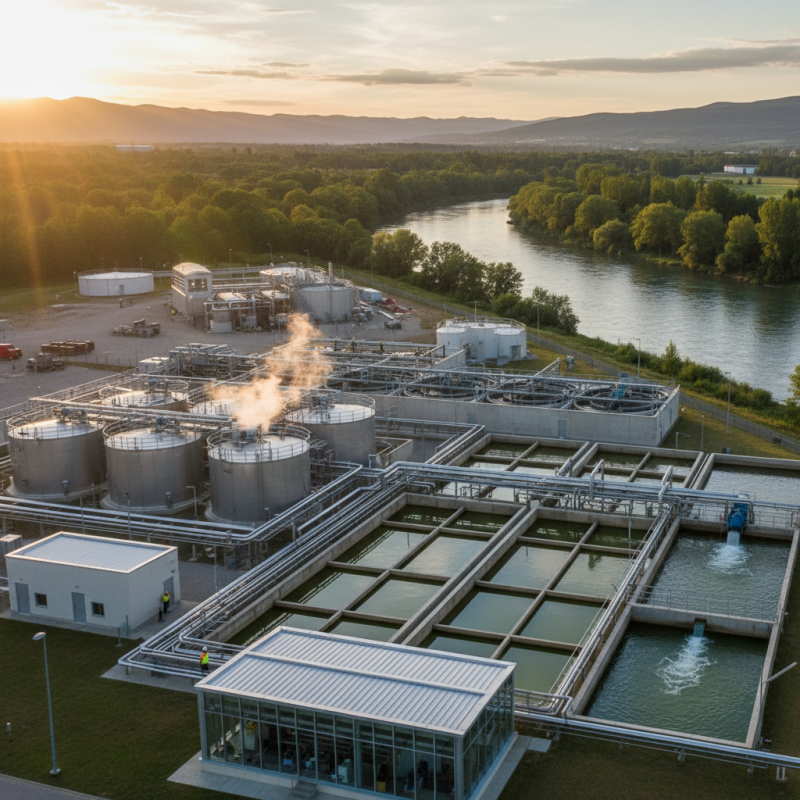

Choosing the right industrial waste water treatment systems is a critical decision for any business involved in manufacturing or processing. As these systems are essential in managing the environmental impact of industrial activities, their selection hinges on a variety of factors including system efficiency, regulatory compliance, and the specific needs of the facility. According to Dr. Emily Carter, a leading expert in environmental engineering, “The right waste water treatment system not only protects our water resources but also can enhance the sustainability profile of any industrial operation.”

In the evolving landscape of environmental regulations and sustainability goals, businesses must navigate a complex array of technology options available in the market. This requires an understanding of the unique characteristics of their waste stream, the local regulations they must comply with, and the available budget. As industries strive to minimize their ecological footprint, effective industrial waste water treatment systems have emerged as a pivotal element in promoting operational efficiency and corporate responsibility.

Understanding the nuances of various treatment technologies, from biological treatments to advanced filtration processes, is essential for selecting the most suitable system. By making informed choices, companies can improve their environmental performance while ensuring compliance and operational reliability.

Understanding Industrial Waste Water Treatment Systems

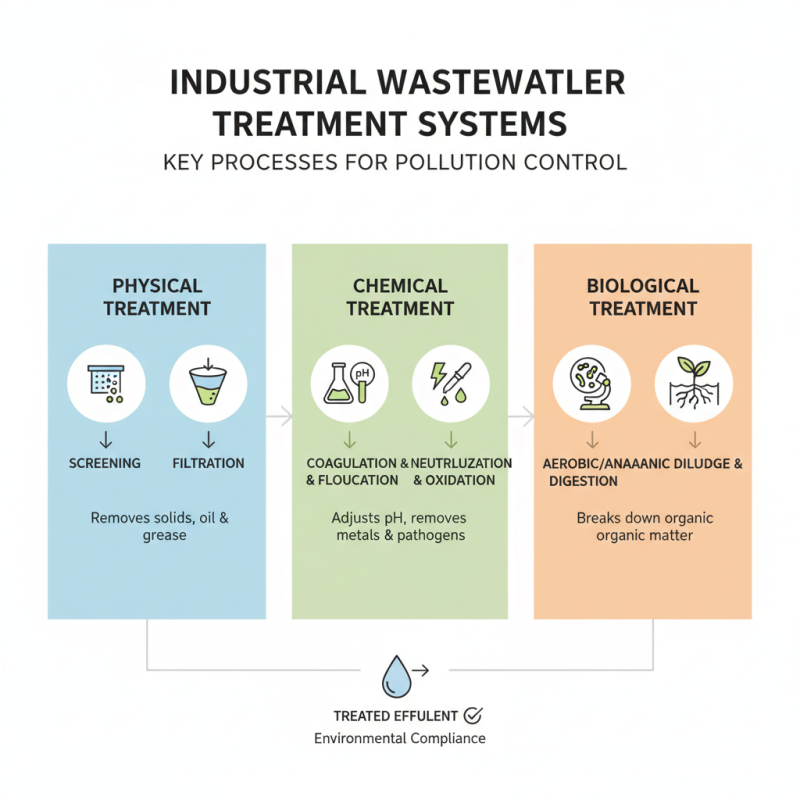

Understanding industrial wastewater treatment systems is crucial for businesses seeking to manage their waste effectively. These systems are designed to remove contaminants from wastewater generated by industrial processes, ensuring that the effluent meets environmental standards before being discharged. Generally, these systems can vary widely based on the type of industry, the volume of wastewater produced, and the specific contaminants present. Common treatment methods include physical, chemical, and biological processes, each tailored to address different treatment goals.

When selecting a wastewater treatment system, consider the specific requirements of your operations. One crucial tip is to conduct a thorough analysis of your wastewater characteristics. Understanding the pollutants, their concentrations, and the treatment goals will help in choosing the most efficient system. Additionally, evaluating the system’s capacity and scalability is essential, especially if your production volumes may change in the future.

Another important consideration is maintenance and operational costs. Look for systems that not only meet your treatment needs but also offer ease of maintenance and operational efficiency. A well-maintained system can significantly reduce long-term costs and improve productivity. Don’t forget to assess the technological compatibility with your existing infrastructure to ensure a smoother integration process.

Assessing Your Specific Waste Water Treatment Needs

When considering the selection of an effective industrial wastewater treatment system, the first step is to assess your specific wastewater treatment needs. Begin by analyzing the type and volume of wastewater your operation generates. This includes understanding the nature of the contaminants present, whether they are biological, chemical, or physical. Furthermore, evaluating the necessary treatment goals, such as achieving certain discharge standards or the potential for water reuse, is crucial in informing your system choice.

Tips: Create a comprehensive checklist that outlines your wastewater's characteristics, treatment objectives, and regulatory compliance requirements. This will guide you in selecting a system that not only meets your needs but also aligns with environmental standards.

Another key factor is the operational capacity and space constraints of your facility. Consider how much land or space you can allocate for the treatment system, as well as the availability of utilities such as electricity and water. Take into account the maintenance requirements and technical expertise required for the selected system to ensure long-term efficiency.

Tips: Consult with industry experts or conduct a feasibility study to identify system options that fit within your operational parameters. Networking with other businesses that have faced similar wastewater challenges can also provide valuable insights into effective treatment technologies.

Assessment of Industrial Waste Water Treatment Needs

Evaluating Different Types of Treatment Technologies

When selecting the best industrial wastewater treatment systems for specific requirements, it is crucial to evaluate a variety of treatment technologies available in the market. Different industries generate diverse types of wastewater, each requiring tailored solutions. For instance, the type of contaminants, their concentrations, and the regulatory standards significantly influence the choice of treatment technologies. According to a report by the Water Environmental Federation, approximately 85% of wastewater treatment facilities in the U.S. utilize biological treatment processes. This method is favored for its cost-effectiveness and efficiency in breaking down organic pollutants.

Furthermore, advanced technologies such as membrane filtration and advanced oxidation processes are gaining traction due to their ability to remove micro-pollutants and pathogens more effectively. The Global Market Insights report highlights that the demand for membrane bioreactors (MBRs) is expected to grow at a CAGR of over 10% from 2021 to 2027. These technologies not only enhance the quality of treated water but also allow for water reuse applications, which are becoming increasingly essential in regions facing freshwater scarcity. As industries weigh their options, understanding these different treatment technologies and their performance metrics will lead to more informed choices suited to their specific operational needs.

Comparing Cost, Efficiency, and Compliance Factors

When choosing the best industrial wastewater treatment system, it is essential to consider three key factors: cost, efficiency, and compliance. First, the cost of a treatment system can vary widely based on its design, complexity, and operational requirements. Initial capital costs must be weighed against long-term operational expenses, including energy consumption, maintenance, and replacement parts. Analyzing the total cost of ownership can help businesses ensure that their chosen system aligns with both their budget and their operational needs.

Efficiency is another critical element in selecting a wastewater treatment solution. A system’s ability to remove contaminants effectively while minimizing resource use directly impacts operational efficiency and overall productivity. Technologies that offer advanced filtration, biological treatment, or chemical processes can vary in performance, depending on the specific contaminants present in the wastewater. Evaluating the system’s efficiency in relation to throughput and output quality will help organizations achieve their treatment goals while maximizing resource utilization.

Lastly, compliance with local and international regulations cannot be overlooked. Ensuring that a wastewater treatment system meets legal requirements is essential for avoiding fines and potential shutdowns. This aspect involves understanding the specific discharge standards that apply to the industry and ensuring that the chosen system is capable of meeting or exceeding these regulations. Regular consultations with environmental experts can provide insights into compliance expectations and help identify systems that maintain adherence to evolving standards.

How to Choose the Best Industrial Waste Water Treatment Systems for Your Needs - Comparing Cost, Efficiency, and Compliance Factors

| System Type | Cost (USD) | Efficiency (%) | Compliance Rating |

|---|---|---|---|

| Activated Sludge System | $150,000 | 90 | A |

| Membrane Bioreactor | $250,000 | 95 | A+ |

| Dissolved Air Flotation | $100,000 | 85 | B |

| Sequencing Batch Reactor | $120,000 | 88 | A |

| Constructed Wetlands | $80,000 | 80 | C |

Selecting the Right Supplier and Service Provider

When selecting the right supplier and service provider for industrial wastewater treatment systems,

it's crucial to consider several key factors that can significantly impact the efficiency and

effectiveness of your systems. According to a recent report by the Water Environment Federation,

nearly 80% of industrial facilities are now focusing on

sustainability and

regulatory compliance in their wastewater management strategies. Therefore, choosing a partner that

not only offers robust technology but also aligns with your operational goals is essential.

Additionally, conducting thorough research into potential suppliers is vital. This includes evaluating

their track record, customer reviews, and case studies that demonstrate their capabilities in handling

specific wastewater challenges. According to the U.S. Environmental Protection Agency,

industries that engage with certified professionals often see a 30% reduction in

operational costs due to optimized treatment processes and improved regulatory compliance. Look for vendors who

offer comprehensive services, from design to maintenance, ensuring that you

are supported at every stage of the treatment process.

Tips: Always request detailed proposals from multiple suppliers to compare

their offerings. Check if they provide ongoing training and support to your staff, which can enhance the overall

effectiveness of your wastewater management. Lastly, consider suppliers with a strong commitment to innovation and

who invest in research and development, as this will ensure that you have access to the latest technologies in

wastewater treatment.

Related Posts

-

2025 How to Optimize Waste Water Systems for Sustainability and Efficiency

-

How to Choose the Right Wastewater Package Plant for Your Needs

-

How to Optimize Sewage Water Treatment for Environmental Sustainability

-

What Are Waste Water Treatment Systems and How Do They Work?

-

What is the Role of Waste Water Treatment Plants in Sustainable Water Management?

-

10 Innovative Methods for Effective Waste Water Removal You Need to Know