How to Choose the Right Submersible Mixer for Your Water Treatment Needs

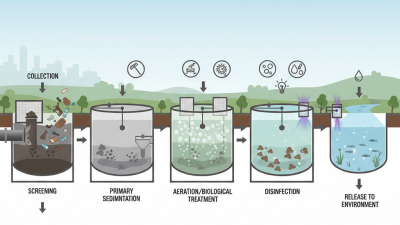

When it comes to optimizing water treatment processes, selecting the appropriate equipment is crucial for achieving the desired efficiency and effectiveness. One of the essential components in many water treatment facilities is the submersible mixer. This innovative device plays a significant role in the homogenization of wastewater, ensuring that the various constituents are evenly mixed, which facilitates both biological and chemical processes necessary for treating water. However, with a multitude of options available on the market, choosing the right submersible mixer tailored to your specific needs can be a complex task.

Several factors come into play when selecting a submersible mixer, including the specific application requirements, the characteristics of the liquid being treated, and the desired mixing performance. Understanding these parameters is vital, as the right mixer can enhance treatment efficiency, reduce energy consumption, and minimize maintenance needs. This introduction aims to guide readers through the key considerations in selecting the most suitable submersible mixer for their water treatment needs, ensuring that they make an informed decision that leads to optimal operational outcomes.

Understanding the Role of Submersible Mixers in Water Treatment

Submersible mixers play a critical role in water treatment processes by enhancing mixing efficiency and ensuring uniform distribution of chemical additives throughout the treatment tank. These mixers aid in the homogenization of sludge, which is essential for optimizing the biological treatment processes. According to industry reports, effective mixing can reduce sedimentation rates by up to 30%, thereby improving the overall treatment performance and reducing operational costs. This efficiency is particularly vital in large-scale municipal wastewater treatment facilities that manage millions of gallons daily, where even minor improvements in mixing can lead to significant cost savings and enhanced treatment effectiveness.

Furthermore, submersible mixers contribute to various operational aspects, such as preventing the formation of odor and maintaining the appropriate microbial activity necessary for biological processes. The global water treatment equipment market is expected to reach USD 88.4 billion by 2025, with a compound annual growth rate (CAGR) of 6.2% from 2020 to 2025, underscoring the growing demand for efficient mixing solutions in water treatment applications. By understanding the mechanistic needs of their specific systems, operators can select the most appropriate submersible mixer that not only meets the mixing requirements but also complies with energy-efficient standards, ensuring sustainable operation in the water treatment sector.

Key Factors to Consider When Selecting a Submersible Mixer

When selecting a submersible mixer for water treatment, several key factors should guide your decision-making process. First and foremost, consider the design and construction materials of the mixer. It is essential to choose a unit made from durable, corrosion-resistant materials that can withstand the unique chemical and physical environment of the water treatment facility. The mixer should also feature an appropriate impeller design that matches the specific mixing requirements of your application, whether it be for aeration, homogenization, or sludge handling.

Another critical factor to evaluate is the mixer’s power and efficiency. Assess the horsepower needed based on the volume and viscosity of the liquids being mixed. A more powerful mixer may be required for denser materials or larger volumes, ensuring effective mixing and optimal performance. Additionally, energy efficiency is paramount in reducing operational costs over time. It’s advisable to look for mixers with variable speed drives, which allow for adjustments in mixing intensity based on real-time demands, enhancing both performance and energy efficiency. Finally, reviewing maintenance requirements and ease of installation can provide insights into the long-term viability of the mixer in your water treatment process.

Submersible Mixer Selection Factors

Types of Submersible Mixers and Their Applications

When selecting a submersible mixer, understanding the different types and their applications is essential for optimal water treatment. There are primarily three types of submersible mixers:

mechanical mixers,

hydraulic mixers, and

aeration mixers.

Mechanical mixers utilize a rotating impeller to create flow and promote uniform mixing in large tanks, making them ideal for applications requiring consistent homogeneity.

Hydraulic mixers, on the other hand, rely on water currents to induce mixing and are best suited for larger bodies of water where mechanical installation is challenging.

Aeration mixers combine mixing and aeration, facilitating oxygen transfer in biological treatment processes, crucial for effective wastewater management.

Tips for choosing the right mixer include considering the specific volume and shape of your treatment tank.

A larger tank may require multiple mechanical mixers to ensure thorough mixing, while smaller spaces might benefit from a single, efficiently positioned hydraulic mixer.

Additionally, assess the type of waste being treated, as certain mixers are more effective with specific waste viscosities.

Always prioritize energy efficiency and maintenance requirements to ensure the long-term functionality of the mixer in your water treatment operations.

Evaluating Performance: Capacity, Power, and Efficiency Requirements

When selecting a submersible mixer for water treatment, understanding the performance metrics of capacity, power, and efficiency is crucial. First, assess the capacity of the mixer based on your specific water treatment application. This involves calculating the total volume of the tank or basin to be mixed. A mixer with the appropriate capacity ensures adequate mixing and avoids issues like sediment build-up or stratification of contaminants.

Power is another critical factor. The motor size directly impacts the mixer’s ability to handle thicker sludge or higher viscosity liquids. It is vital to choose a mixer that has enough power to achieve the desired flow pattern without overworking the equipment, which can lead to premature failures.

Tips: Always consult with a mixing expert or engineer when determining power requirements. Additionally, consider the energy efficiency of the mixer; selecting a model with energy-saving capabilities can significantly reduce operating costs over time. Finally, take into account the efficiency of the mixer during different operational conditions to ensure optimum performance across varying loads.

Maintenance and Operational Considerations for Submersible Mixers

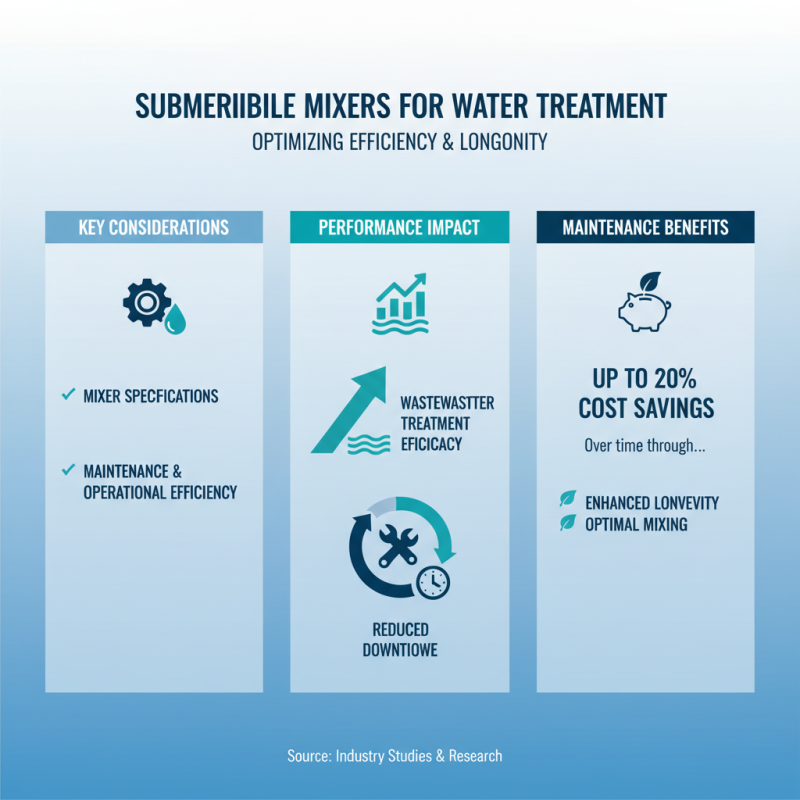

When selecting a submersible mixer for water treatment applications, it's essential to consider not only the mixer's specifications but also its maintenance and operational efficiency. According to industry studies, the efficacy of submersible mixers can significantly impact the overall performance of wastewater treatment facilities. Regular maintenance can enhance the longevity of the mixer, reduce downtime, and ensure optimal mixing efficiency. Research indicates that properly maintaining these devices can lead to operational cost savings of up to 20% over time.

One key operational consideration is the frequency of maintenance checks. It is recommended to perform visual inspections every month, checking for any abnormal vibrations or unusual noises. Additionally, lubricating moving parts according to the manufacturer’s guidelines can prevent wear and tear. Tips for efficient maintenance include keeping an organized maintenance log and addressing any issues as soon as they arise to prevent larger problems.

Another important aspect is the mixer’s operational settings, which should be adjusted based on the conditions of the wastewater being treated. Depending on the composition of the wastewater, different mixing intensities may be necessary. According to the American Society of Civil Engineers, improper mixing can lead to sediment buildup, affecting treatment quality. Therefore, operators should regularly monitor and adjust mixer speed and operational time to ensure optimal dispersion, aiming for a uniform mixture that enhances treatment processes.

Related Posts

-

Transforming Industrial Waste Water Treatment Solutions at the 138th Canton Fair 2025 for a Sustainable Future

-

What is Waste Water Removal and Its Importance in Environmental Sustainability

-

Exploring Innovations in Sewer Treatment Plants at China Import and Export Fair 2025

-

Top 10 Waste Water Treatment Systems Revolutionizing Water Management with 70 Percent Efficiency Improvement

-

Top 7 Wastewater Treatment Systems: Upgrade Your Water Management Solutions Today!

-

What is the Wastewater Treatment Process Explained in Simple Terms