How to Design and Optimize a Sewer Treatment Plant for Maximum Efficiency

In the quest to design and optimize a sewer treatment plant for maximum efficiency, industry experts stress the importance of innovative engineering and sustainable practices. Dr. Jane Thompson, a leading authority in wastewater management, once stated, "The efficiency of a sewer treatment plant is not just about technology; it's about harmonizing systems to work seamlessly together." This insight reflects the core principle behind modern sewer treatment facilities, where the integration of advanced technologies and ecological considerations can significantly enhance performance.

As urban populations continue to grow, the demand for effective wastewater treatment becomes increasingly critical. A well-designed sewer treatment plant not only ensures the protection of public health and the environment but also maximizes resource recovery. By focusing on optimizing processes, such as biological treatment methods and energy efficiency, engineers can create systems that reduce operational costs while meeting regulatory standards. The challenge lies in balancing these factors to produce a sewer treatment plant that is both economically viable and environmentally sustainable, paving the way for future innovations in the field.

Understanding the Basics of Sewer Treatment Plant Design

Designing an efficient sewer treatment plant requires a comprehensive understanding of the fundamental principles of wastewater management. A well-designed plant begins with a clear understanding of the influent characteristics, including flow rates, biochemical oxygen demand (BOD), and total suspended solids (TSS). According to the Water Environment Federation, effective preliminary design must account for peak flow variations and the plant's capacity to handle these fluctuations. For instance, a plant designed to manage a steady flow of 1 million gallons per day should include measures to effectively treat up to 1.5 million gallons during peak periods, ensuring the system can maintain compliance with environmental discharge regulations.

Moreover, optimizing the treatment processes involves selecting the appropriate combination of physical, biological, and chemical treatment methods. Studies have shown that integrating advanced technologies such as membrane bioreactors (MBRs) can enhance the removal of pollutants, achieving TSS and BOD reductions of over 90%, compared to traditional methods. The U.S. Environmental Protection Agency's (EPA) guidelines emphasize that the energy efficiency of treatment plants can also be significantly improved by utilizing anaerobic digestion, which not only reduces waste volume but also generates biogas that can be used for energy recovery. Therefore, understanding these design fundamentals and applying best practices ensures that sewer treatment plants not only meet regulatory requirements but also operate at maximum efficiency.

Efficiency of Different Treatment Processes in Sewer Treatment Plants

Key Components of an Efficient Sewer Treatment Plant

An efficient sewer treatment plant is composed of several key components that work together to ensure the effective processing of wastewater. The primary elements include the screening system, which removes large debris and solids from incoming sewage, and the sedimentation tanks, which allow heavier particles to settle at the bottom through gravity. This initial phase is crucial for minimizing the load on subsequent treatment processes and enhancing the overall efficiency of the plant.

Another vital component is the biological treatment stage, which typically involves aeration tanks where microorganisms break down organic matter. This process is essential for reducing biochemical oxygen demand (BOD) and helps achieve higher levels of effluent quality. Additionally, advanced treatment features like membrane bioreactors or reverse osmosis can further refine the water, preparing it for safe release into the environment or potential reuse. Incorporating efficient pumping systems and monitoring technologies also plays a significant role in optimizing energy consumption and maintaining operational effectiveness, resulting in a sewer treatment plant that operates at maximum efficiency.

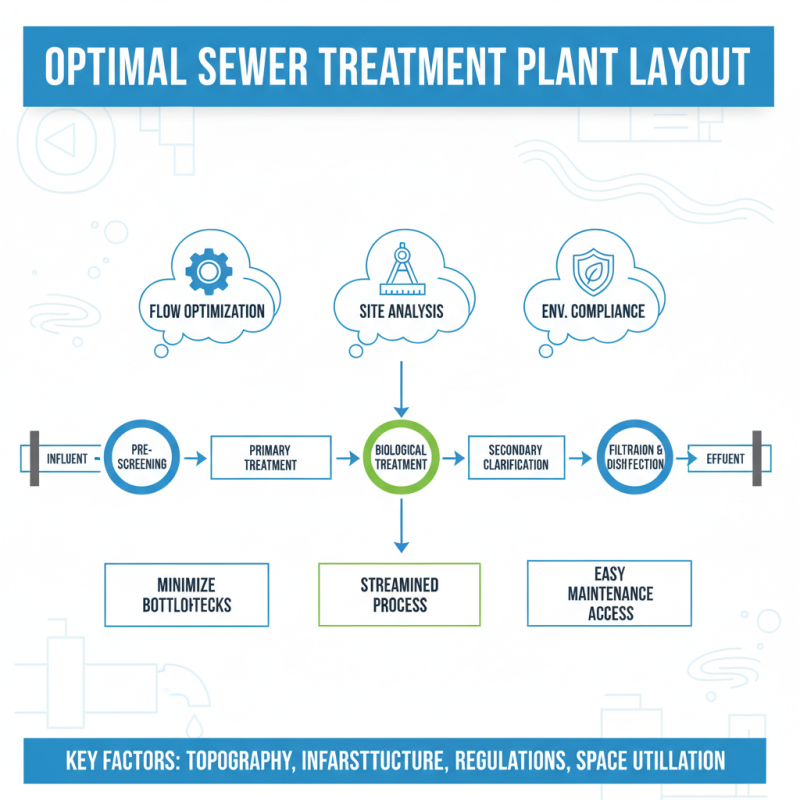

Strategic Planning for Optimal Plant Layout and Flow Management

Effective flow management and strategic planning are crucial for the optimal layout of a sewer treatment plant. A well-designed plant will streamline the flow of wastewater, minimizing bottlenecks and ensuring that each stage of treatment operates smoothly. This involves analyzing the site conditions thoroughly and considering factors such as topography, existing infrastructure, and environmental regulations. The layout should facilitate easy access for maintenance while also maximizing the use of space for different treatment stages, from preliminary screening to final effluent treatment.

Incorporating advanced technologies and processes is essential to enhance efficiency. For instance, designing an automated flow control system can help regulate the volume of wastewater entering the treatment plant, optimizing energy consumption and chemical usage. Additionally, strategically placing treatment units in relation to each other can reduce the distance wastewater must travel, thereby minimizing energy loss and potential contamination risks. By prioritizing these elements during the planning phase, operators can create a functional and efficient sewer treatment plant that effectively addresses community needs while adhering to environmental standards.

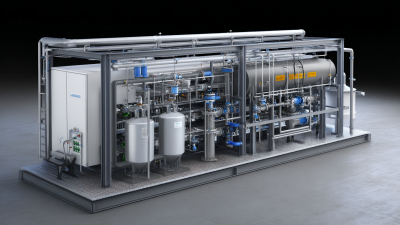

Innovative Technologies for Enhancing Treatment Efficiency

Innovative technologies are pivotal in enhancing the efficiency of sewer treatment plants, addressing environmental concerns while optimizing resource usage. According to the Water Environment Federation, incorporating advanced treatment methods like membrane bioreactors (MBRs) can reduce wastewater treatment volumes by up to 80%. MBR technology combines biological treatment with membrane filtration, allowing for improved removal of solids and pathogens. This leads to higher-quality effluent, which is crucial for meeting stringent discharge standards and for potential reuse applications.

Additionally, the integration of automation and real-time monitoring systems plays a crucial role in optimizing sewer treatment processes. A report by the International Water Association indicates that facilities utilizing automated monitoring can achieve a 30% reduction in operational costs through better management of energy and chemicals. Real-time data analytics can help operators make informed decisions, improving response times to fluctuations in influent quality and volume. As these innovative technologies continue to evolve, they offer wastewater treatment facilities the tools necessary to enhance efficiency and sustainability, ensuring that they meet modern environmental standards.

Maintenance Practices for Sustaining Long-Term Plant Performance

Proper maintenance practices play a crucial role in sustaining the long-term performance of sewer treatment plants. According to a report by the Water Environment Federation, routine maintenance can enhance the operational efficiency of treatment facilities by up to 30%. Regular inspections, preventive maintenance, and timely equipment replacement contribute significantly to reducing the likelihood of system failures, ultimately leading to lower operational costs and improved wastewater quality. Key tasks such as cleaning screens, maintaining motors, and monitoring chemical dosing systems not only ensure optimal performance but also extend the lifespan of critical components.

Furthermore, effective data management techniques are essential for optimizing maintenance schedules. By implementing an Asset Management System (AMS), utilities can track the performance of individual components and identify patterns that indicate potential issues before they escalate. The American Society of Civil Engineers highlights that integrating data analytics into maintenance strategies can lead to a 20-40% reduction in lifecycle costs. Regular training for maintenance personnel on the latest practices and technologies is also vital to keeping up with advancements in treatment processes and ensuring the plant operates at peak efficiency. By prioritizing consistent maintenance and incorporating innovative monitoring techniques, sewer treatment plants can maintain high performance levels and effectively meet regulatory standards over time.

How to Design and Optimize a Sewer Treatment Plant for Maximum Efficiency - Maintenance Practices for Sustaining Long-Term Plant Performance

| Maintenance Practice | Frequency | Estimated Cost ($) | Expected Lifespan Increase (%) | Notes |

|---|---|---|---|---|

| Routine Inspections | Monthly | 500 | 10 | Identifies potential issues early |

| Chemical Dosing Adjustment | Weekly | 300 | 15 | Optimizes treatment efficiency |

| Filter Cleaning | Quarterly | 1200 | 12 | Prevents clogging and maintains flow |

| Pump Maintenance | Biannual | 2500 | 20 | Ensures optimal pump operation |

| Sludge Management | Annually | 7000 | 25 | Reduces overflow risks |

Related Posts

-

Top 10 Effective Waste Water Treatment Methods You Need to Know

-

Exploring Innovations in Package Wastewater Treatment Plants at the 138th Canton Fair 2025

-

Exploring Innovations in Sewer Treatment Plants at China Import and Export Fair 2025

-

What is the Role of Waste Water Treatment Plants in Sustainable Water Management?

-

Innovative Solutions for Effective Industrial Waste Water Treatment Systems

-

Understanding the Essential Steps in the Wastewater Treatment Plant Process