10 Essential Tips for Choosing the Right Centrifugal Pump for Your Needs

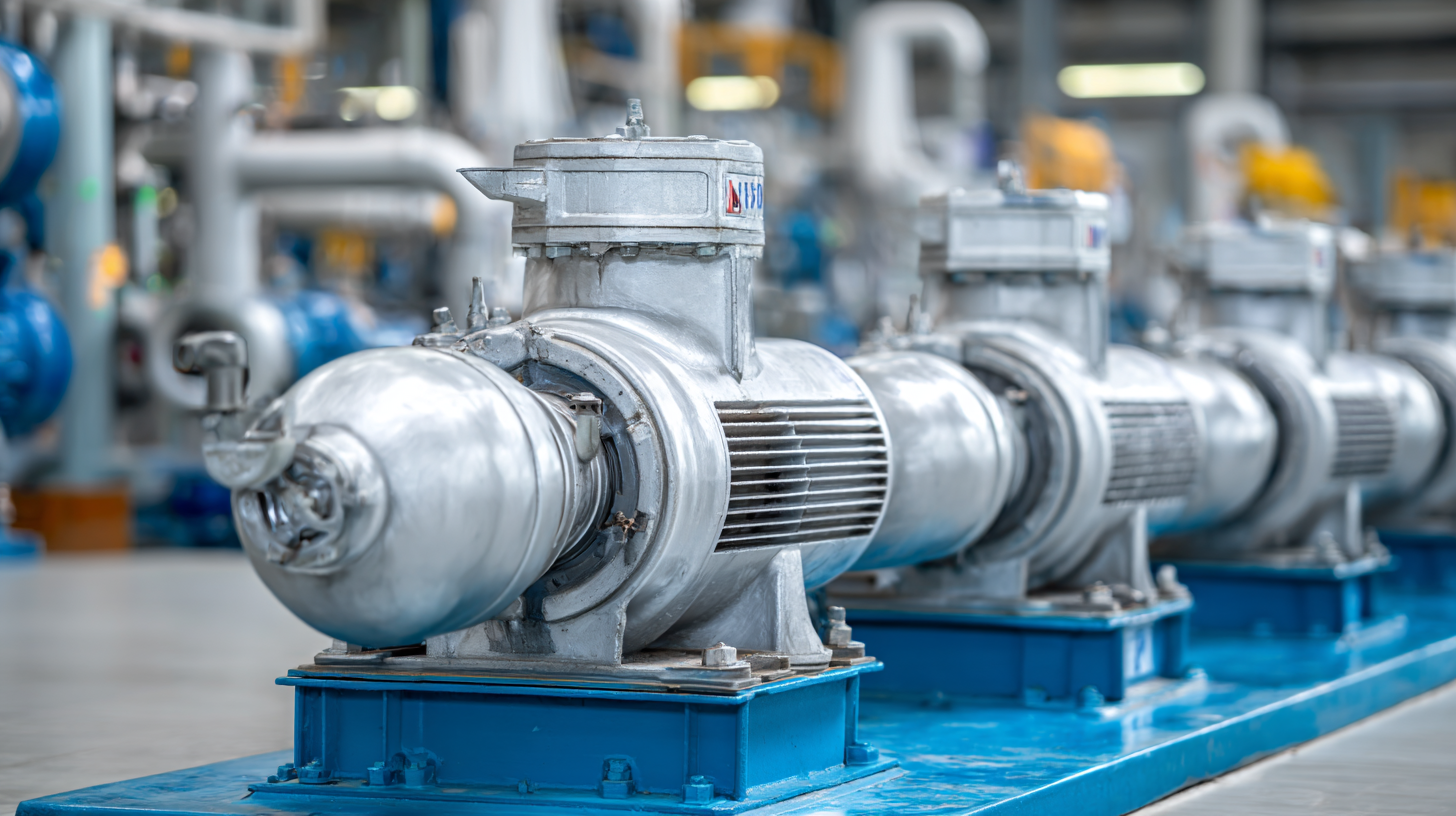

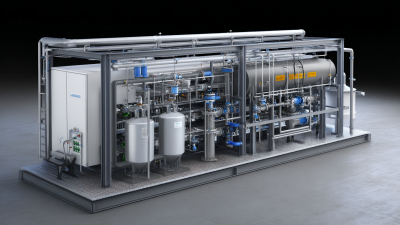

Choosing the right centrifugal pump for your specific application is a critical decision that can greatly impact efficiency and operational costs. According to the latest industry report by the Engineering Equipment and Materials Users Association (EEMUA), the global centrifugal pump market is expected to reach $40 billion by 2025, driven by increased demand in sectors such as water treatment, oil and gas, and chemical processing. With a myriad of options available, understanding the nuances of centrifugal pump design, performance, and application becomes essential for procurement professionals and engineers alike.

Industry expert Dr. Emma L. Caldwell, a recognized leader in pump technology, emphasizes the importance of this decision: "Selecting the right centrifugal pump not only ensures optimal performance but also enhances system reliability, reducing downtime and maintenance costs." Her insights reflect the necessity of aligning pump selection with system requirements, which can be influenced by factors such as fluid properties, flow rates, and application conditions. With the advent of advanced technology and materials, today's centrifugal pumps offer improved efficiencies and capabilities that can cater to increasingly demanding industrial needs.

In this article, we present ten essential tips to aid in the selection of the perfect centrifugal pump for your needs, ensuring that you make informed decisions that will benefit both your immediate projects and long-term operational goals.

Factors to Consider When Assessing Pump Application Requirements

When selecting a centrifugal pump for specific applications, understanding the pump application requirements is crucial. Factors such as fluid type, temperature, viscosity, and flow rate must be assessed. According to a report by the Hydraulic Institute, about 20% of pump failures are attributed to poor application assessment. Ensuring compatibility with the fluid being pumped can significantly reduce maintenance costs and extend service life.

Another essential aspect is the required flow rate and head. It’s vital to calculate the total dynamic head (TDH) accurately. As highlighted by the American Society of Mechanical Engineers, for optimal flow, pumps should not operate below 30% of their Best Efficiency Point (BEP). This helps in avoiding issues such as cavitation and excessive wear.

Tip: Always consider the installation environment. For example, if a pump is to be placed outdoors, opting for corrosion-resistant materials can mitigate long-term degradation. Additionally, assessing the availability of spare parts and local support can greatly influence the pump's performance and reliability over time.

10 Essential Tips for Choosing the Right Centrifugal Pump

This chart highlights key specifications to consider when selecting a centrifugal pump, including flow rate, total head, efficiency, pump size, and power requirements. Make sure to evaluate these factors based on your specific application needs.

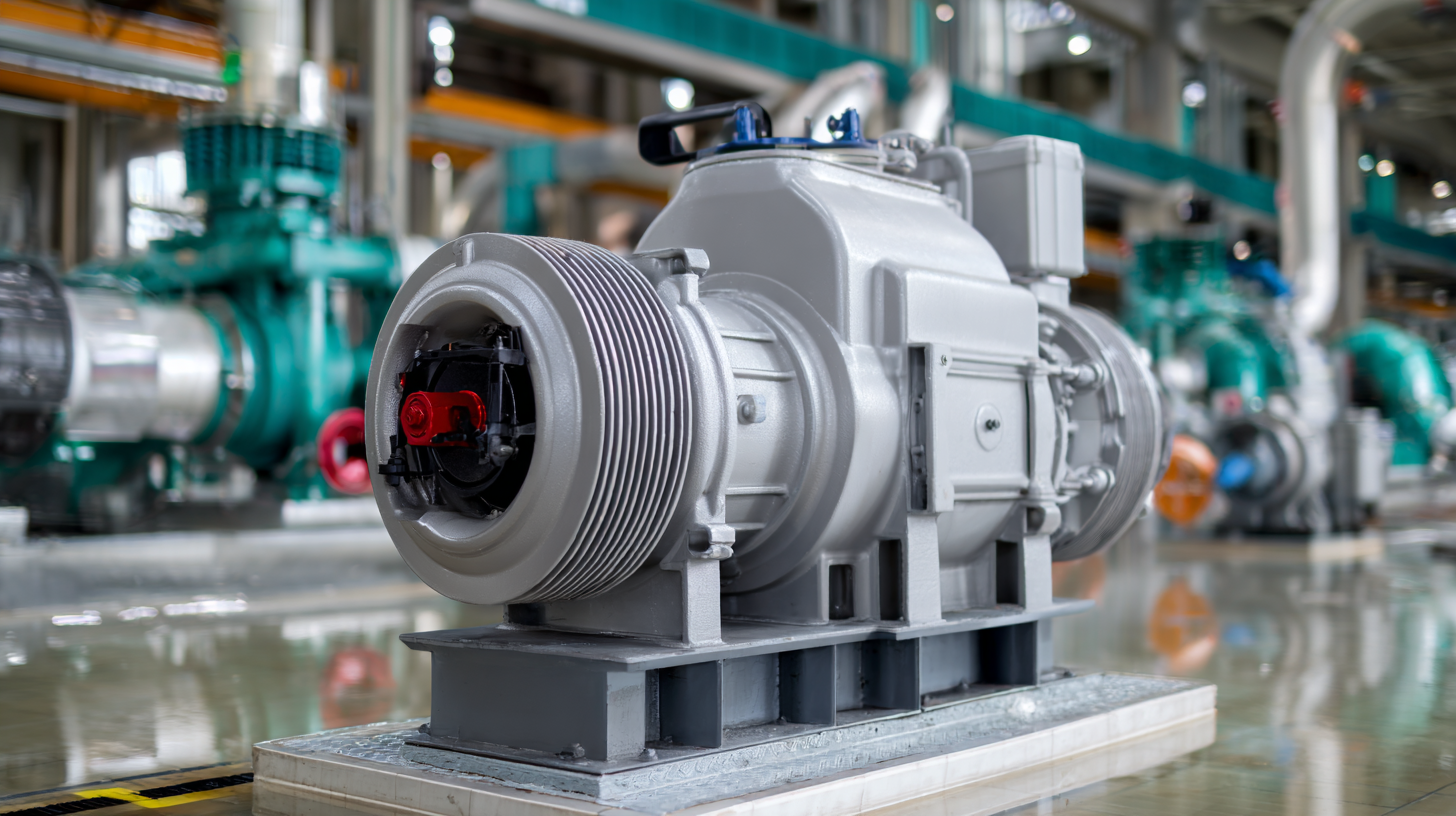

Understanding Pump Specifications: Flow Rate, Head, and Efficiency

When selecting a centrifugal pump, understanding key specifications such as flow rate, head, and efficiency is crucial for making an informed decision. The flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s), indicates the volume of liquid the pump can move. It's essential to choose a pump that matches the specific requirements of your application, as an inadequate flow rate can lead to inefficiencies or insufficient system performance.

Head, defined as the height to which a pump can raise fluid, is another critical specification. It encompasses both the static lift, which is the vertical distance the fluid must travel, and the friction loss within the system. Ensuring that the selected pump can achieve the required head is vital, as pumps operating below their optimal capacity may lead to reduced efficiency and increased wear over time. Additionally, consider the pump's efficiency, often represented as a percentage, which reflects how effectively it converts mechanical energy into hydraulic energy. Higher efficiency pumps can result in lower operational costs and reduced energy consumption, making them a smarter choice for sustainable operations.

Evaluating Material Compatibility for Long-lasting Performance

When selecting a centrifugal pump, one critical aspect to consider is material compatibility. The choice of materials significantly impacts the pump's lifespan and effectiveness, especially in harsh environments. Research from the Hydraulic Institute indicates that improper material selection can lead to premature wear or pump failure, with costs associated with unplanned downtime and replacements reaching up to 20% of the annual maintenance budget for industrial facilities.

Different applications require specific materials due to varying chemical exposures and temperature conditions. For instance, stainless steel is often favored for its corrosion resistance when handling aggressive fluids, while thermoplastics can offer excellent resistance for mildly corrosive substances. According to a report by the American Society of Mechanical Engineers (ASME), approximately 30% of all centrifugal pump failures are linked to corrosion and erosion due to incompatible materials, highlighting the importance of a thorough compatibility assessment before making a purchase.

Evaluating the fluid properties is essential; factors such as pH, temperature, and viscosity can greatly influence material choice. Additionally, consulting with manufacturers and utilizing compatibility charts can provide valuable insights, ensuring the selected pump materials not only meet operational requirements but also enhance longevity and reliability. Remember, investing time in material evaluation up front can save significant costs and headaches in the long run.

Importance of Maintenance and Support in Pump Selection

When selecting the right centrifugal pump, maintenance and support play a crucial role in decision-making. It's essential to consider the manufacturer's reputation for after-sales support. A reliable pump supplier should offer comprehensive maintenance services, ensuring your equipment operates efficiently and lasts longer. This support can include regular servicing, availability of spare parts, and prompt response to any issues that arise. A good relationship with your supplier can help you navigate any challenges and minimize downtime.

Moreover, understanding the maintenance requirements of the pump is vital. Different pumps come with varying maintenance demands, and choosing one that aligns with your operational capabilities can prevent unexpected failures. Regular inspection and timely upkeep should be part of your routine to ensure optimal performance. Assessing the availability of technical support, such as troubleshooting assistance and training, can also enhance your experience with the pump. Ultimately, prioritizing maintenance and support during the selection process not only enhances the pump's reliability but also contributes to long-term operational success.

Budgeting: Cost vs. Value in Centrifugal Pumps Decision Making

When selecting a centrifugal pump, understanding the interplay between cost and value is crucial for making an informed decision. While budget constraints often drive initial purchasing choices, it’s essential to consider the long-term implications of opting for a cheaper model. In many cases, lower upfront costs can lead to higher maintenance expenses, reduced efficiency, and a shorter lifespan. Evaluating the total cost of ownership allows buyers to see past the initial price tag, factoring in operational costs, energy consumption, and potential repair expenses.

Additionally, investing in a higher-quality centrifugal pump can yield significant benefits in the long run. A pump designed for efficiency may cost more initially but can save money through lower energy bills and decreased downtime. It’s important to assess the features that provide added reliability and performance, such as materials used, design innovations, and manufacturer warranties. By aligning your budget with the value offered by premium options, you can ensure that the centrifugal pump you choose not only meets your immediate needs but also serves your operational goals effectively over time.

10 Essential Tips for Choosing the Right Centrifugal Pump for Your Needs - Budgeting: Cost vs. Value in Centrifugal Pumps Decision Making

| Parameter | Description | Cost Range (USD) | Value Assessment |

|---|---|---|---|

| Flow Rate | The volume of fluid a pump can move in a given time period, typically measured in GPM or L/min. | $500 - $3,000 | High flow rates increase efficiency but may lead to higher costs. |

| Head Pressure | The height to which a pump can raise the fluid, measured in feet or meters. | $600 - $4,500 | Higher head pressures can indicate a more robust pump design. |

| Pump Material | The type of material used in pump construction, affecting durability and compatibility with fluids. | $800 - $5,000 | Material impacts longevity and maintenance costs; higher quality materials often equate to better value. |

| Energy Efficiency | The pump’s ability to convert energy into pumping power, often rated by efficiency percentage. | $1,200 - $6,000 | Higher efficiency models reduce energy costs, justifying initial expenditures over time. |

| Maintenance Requirements | The frequency and complexity of maintenance needed for optimal operation. | $200 - $1,500 annually | Investing in lower maintenance pumps may lead to reduced total cost of ownership. |

| Pump Size | Physical dimensions affect installation space and compatibility. | $300 - $2,500 | Larger pumps may incur additional installation costs but can offer higher performance. |

| Warranty | The period during which the manufacturer guarantees the product against defects. | Included in purchase price | A longer warranty typically indicates higher confidence from the manufacturer. |

| Application Compatibility | Suitability of the pump for specific fluids and operating conditions. | N/A | Choosing the right pump for the application ensures efficiency and reduces risks. |

| Installation Costs | Costs associated with setting up the pump, including labor and materials. | $500 - $3,000 | Proper installation is crucial for optimal performance, impacting overall value. |

| Total Cost of Ownership | Cumulative costs over the pump’s lifecycle, including purchase, operation, and maintenance. | $5,000 - $20,000+ | Focus on long-term costs rather than just initial price for best value. |

Related Posts

-

Understanding the Science Behind Centrifugal Pumps in Modern Engineering

-

The Ultimate Guide to Choosing the Right Centrifugal Pump for Your Needs

-

Exploring Innovations in Sewer Treatment Plants at China Import and Export Fair 2025

-

Top 10 Waste Water Treatment Systems Revolutionizing Water Management with 70 Percent Efficiency Improvement

-

10 Innovative Methods for Effective Waste Water Removal You Need to Know

-

Innovative Solutions for Effective Industrial Waste Water Treatment Systems