English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик  简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba

Heavy Type Spring Shot Peening Machines Manufacturers

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for Heavy Type Spring Shot Peening Machines,Shot Peening Machine for Springs,Reasonable Structure Shot Peening Machine for Heavy Type Springs,Low Energy Consumption Shot Peening Machine for Heavy Type Springs,High Efficiency Shot Peening Machine for Heavy Type Springs, If possible, be sure to send your needs with a detailed list including the style/item and quantity you require. We will then deliver our greatest price ranges to you.

Heavy Type Spring Shot Peening Machines, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products and solutions. Our advantage is full category, high quality and competitive price! Based on that, our goods win a high admiration both at home and abroad.

Hot Products

Q32 Tumble Belt Shot Blasting Machine for Brass Fittings Cleaning

Puhua® Q32 Tumble Belt Shot Blasting Machine for Brass Fittings Cleaning This series is used for surface cleaning,rust removing,product intensifying for all kinds of medium and small casting,forging and machinings.It is suitable for different process scale,can work single or medium and small sizes workpieces. Q32 Series tumble belt shot blasting machine has advantages of advanced design,reasonable structure,low energy consumption and high efficiency.Roller Conveyor Blasting And Painting Machine

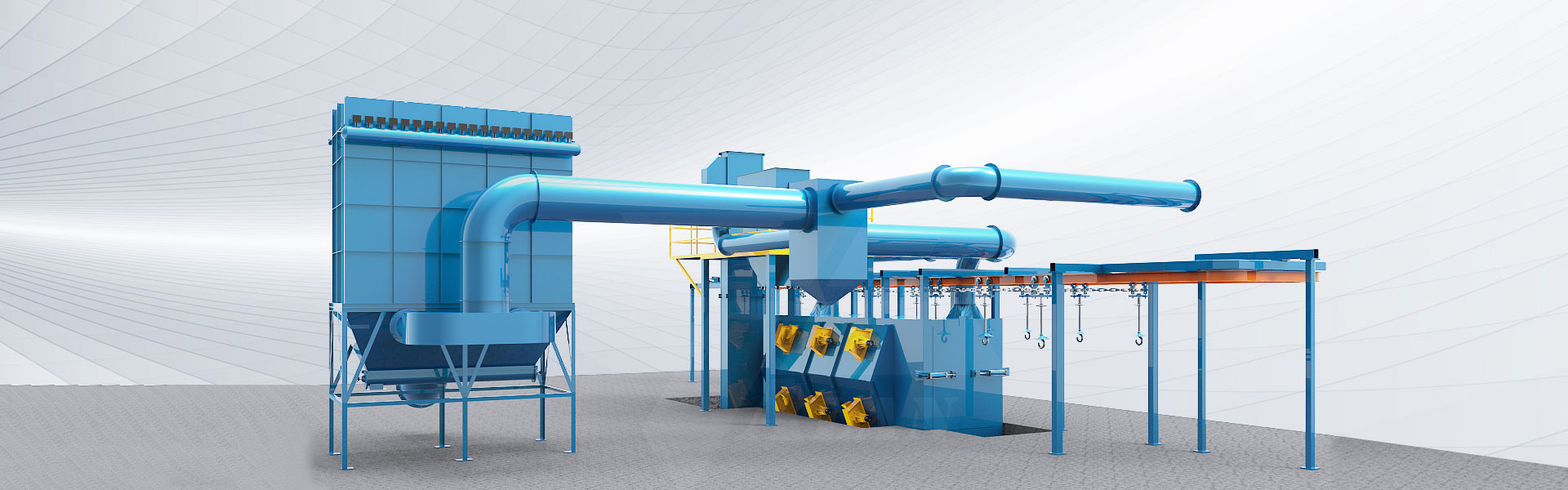

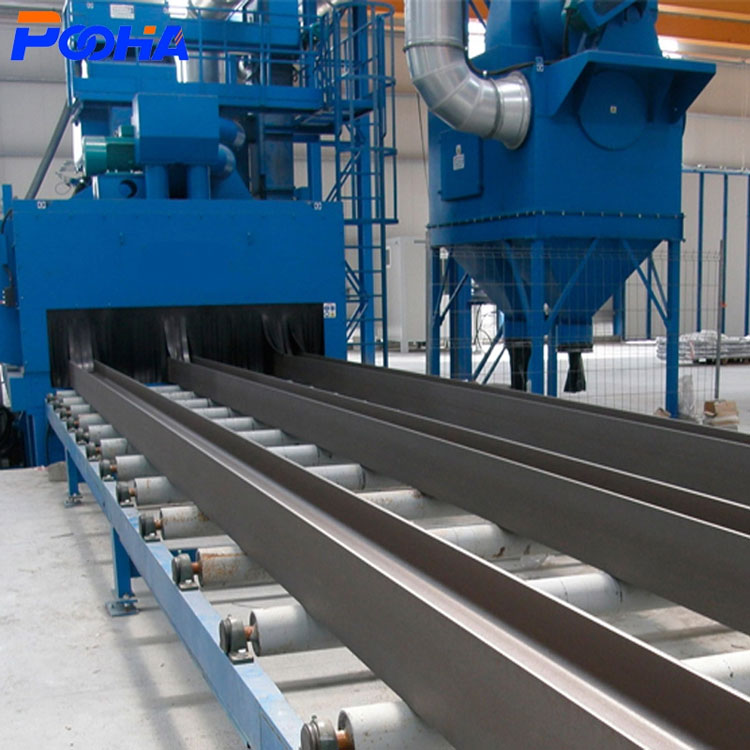

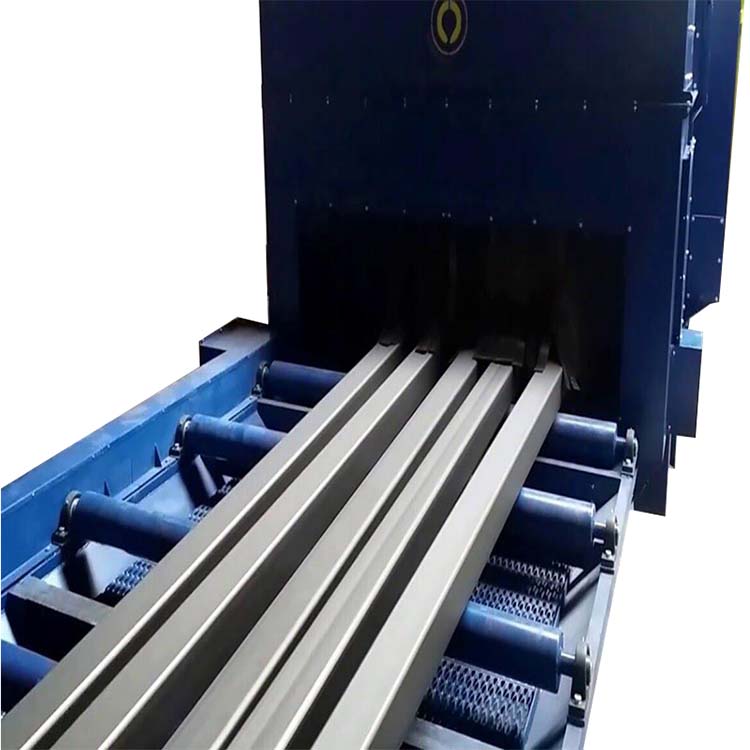

Puhua® Q69 Roller Conveyor Blasting And Painting Machine is used to remove scale and rust from metal profiles and sheet metal components. It applies to surface rusting and painting art of shipping, car, motorcycle, bridge, machinery, etc. By combining a roller conveyor with the appropriate crossover conveyors, individual process steps such as blasting, conservation, sawing and drilling can be interlinked. This ensures a flexible manufacturing process and high material output.Automatic Recovery Recycle System Sand Blasting Booth With Dust Extractor

Puhua® Automatic Recovery Recycle System Sand Blasting Booth With Dust Extractor is widely used in shipbuilding industry, military, and engineering machinery, petrochemical machinery. It could be designed according to customer’s requirements.Steel Tube Rust Remove Shot Blast Cleaning Machine

Puhua® Q69 Steel Tube Rust Remove Shot Blast Cleaning Machine is used to remove scale and rust from metal profiles and sheet metal components. It applies to surface rusting and painting art of shipping, car, motorcycle, bridge, machinery, etc. By combining a roller conveyor with the appropriate crossover conveyors, individual process steps such as blasting, conservation, sawing and drilling can be interlinked. This ensures a flexible manufacturing process and high material output.Road Shot Blasting Machine

Puhua® Road Shot Blasting Machine Function of road surface blasting once will be enough clear away surface laitance of concrete and remove impurities, and can undertake hair treatment on the surface of concrete, make its surface well-distributed roughness, greatly improving the adhesive strength of the waterproof layer and concrete base layer, so that the waterproof layer and bridge deck can better combination, and at the same time the crack of concrete can be fully exposed, have the effect of nip in the bud.Shot Blasting Machine for Sheet Steel

Puhua® Q69 Shot Blasting Machine for Sheet Steel is used to remove scale and rust from metal profiles and sheet metal components. It applies to surface rusting and painting art of shipping, car, motorcycle, bridge, machinery, etc. By combining a roller conveyor with the appropriate crossover conveyors, individual process steps such as blasting, conservation, sawing and drilling can be interlinked. This ensures a flexible manufacturing process and high material output.