English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик  简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba

Steel Plate or Steel Beam Shot Blasting Machine with High Efficiency and Automation Manufacturers

"Based on domestic market and expand abroad business" is our improvement strategy for Steel Plate or Steel Beam Shot Blasting Machine with High Efficiency and Automation,shot blasting machine,Steel Beam Shot Blasting Machine and Steel Bar Shot Blasting Machine,High-performance Steel Plate Shot Blasting Machine,Steel Plate or Steel Beam Shot Blasting Machine with High Efficiency, Now we have established steady and long business relationships with customers from North America, Western Europe, Africa, South America, more than 60 countries and regions.

Steel Plate or Steel Beam Shot Blasting Machine with High Efficiency and Automation, Further, we've been supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to provide our clients an effective range of goods.

Hot Products

H Beam Cleaning Abrator

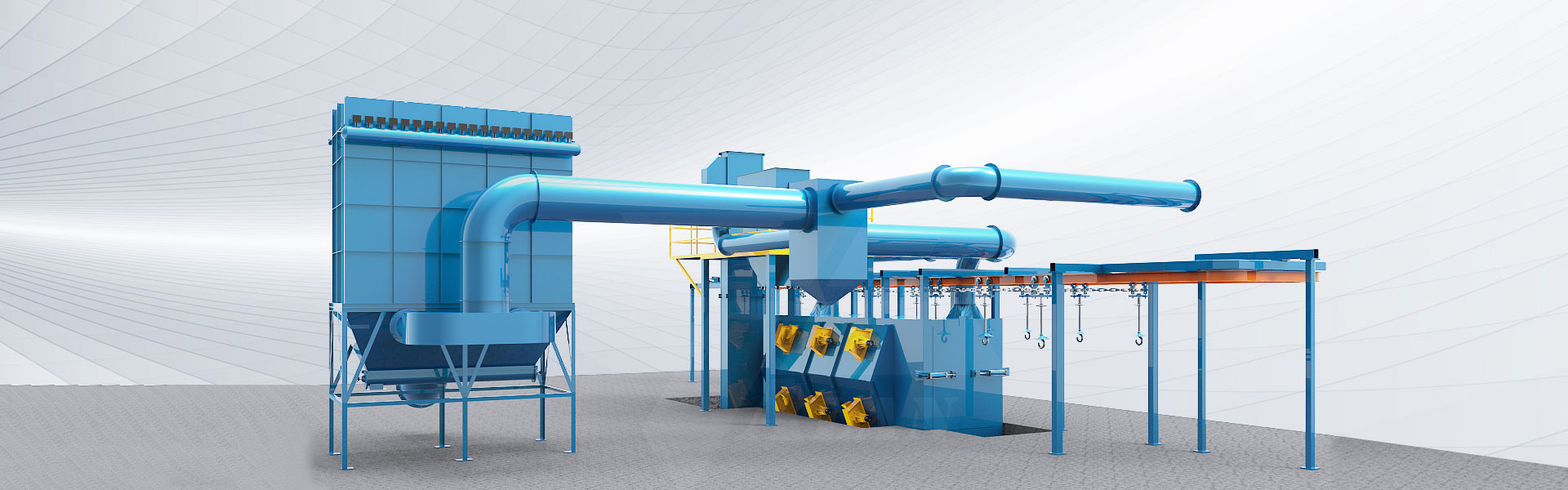

Puhua® Q69 H Beam Cleaning Abrator is used to remove scale and rust from metal profiles and sheet metal components. It applies to surface rusting and painting art of shipping, car, motorcycle, bridge, machinery, etc. By combining a roller conveyor with the appropriate crossover conveyors, individual process steps such as blasting, conservation, sawing and drilling can be interlinked. This ensures a flexible manufacturing process and high material output.Q69 Steel Plate Beam Structure Shot Blasting Painting Machine

Puhua® QG series Q69 Steel Plate Beam Structure Shot Blasting Painting Machine for surface treatment , wiping up the oxide coating , welding slag, appearing the metallic sheen , increasing the area of the surface , which is in favor of UV. It applies in the line of petroleum& chemical , steel , city centralized heating , centralized drainage etc.Steel Pipe Shot Blasting Machine/Steel Pipe Outer Wall Shot Blast Machines is a combination of clean-steel outer wall of cleaning machine, by blasting to clean the outer surface of the steel pipe, shot by throwing inside to clean surface, so that the surface oxide are rid off. It is used before welding or painting on its outer surface treatment of the pipes.Steel Structure Plate Shot Blasting Machine

Puhua® Q69 Steel Structure Plate Shot Blasting Machine is used to remove scale and rust from metal profiles and sheet metal components. It applies to surface rusting and painting art of shipping, car, motorcycle, bridge, machinery, etc. By combining a roller conveyor with the appropriate crossover conveyors, individual process steps such as blasting, conservation, sawing and drilling can be interlinked. This ensures a flexible manufacturing process and high material output.Q326 Tumble Shot Blasting Machine for Small Casting Prod

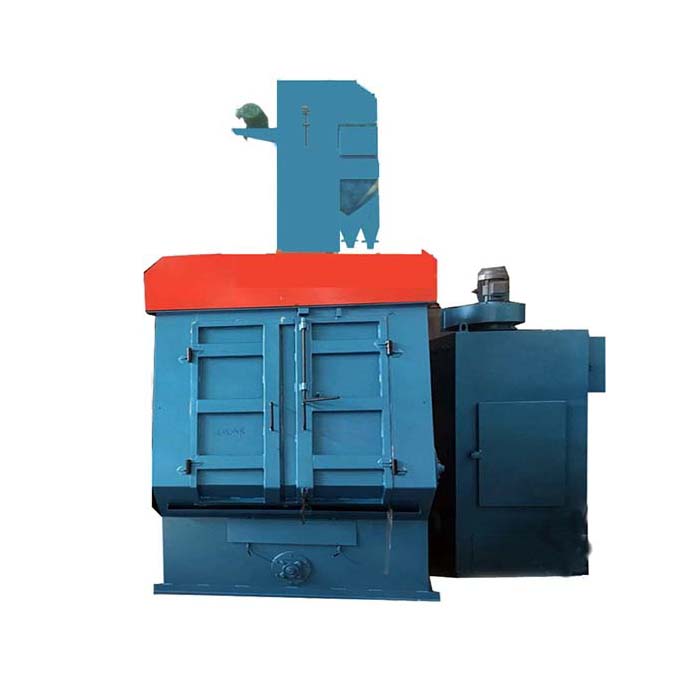

Puhua® Q326 Tumble Shot Blasting Machine for Small Casting Prod This series is used for surface cleaning,rust removing,product intensifying for all kinds of medium and small casting,forging and machinings.It is suitable for different process scale,can work single or medium and small sizes workpieces. Q32 Series tumble belt shot blasting machine has advantages of advanced design,reasonable structure,low energy consumption and high efficiency.Q376 Hook Type Shot Blasting Machine

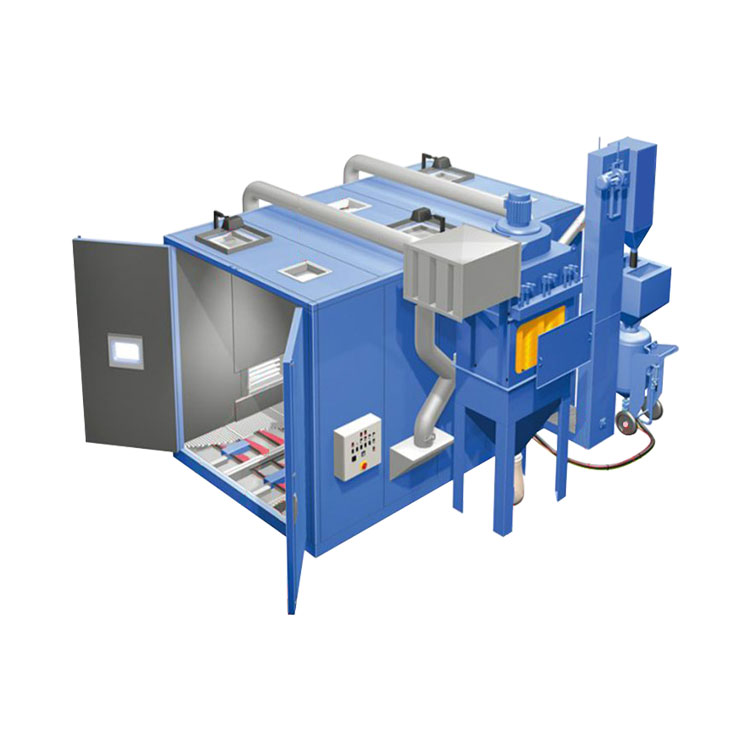

Puhua® Q376 Hook Type Shot Blasting Machine is mainly used for surface cleaning of casting, structure, non-ferrous and other parts. This series shot blasting machine have many types, such as single hook type, double hook type, lifting type, non-lifting type. It has advantage of non-pit, compact structure, high productivity, etc.Shot Blasting Booth

Puhua® shot blasting booth/room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cinder on steel to obtain a uniform, smooth and glossy metal surface allowing improved coating quality and higher anti-corrosion performance, the surface stress of steel is strengthened, and the service life of workpieces is prolonged.